Email:

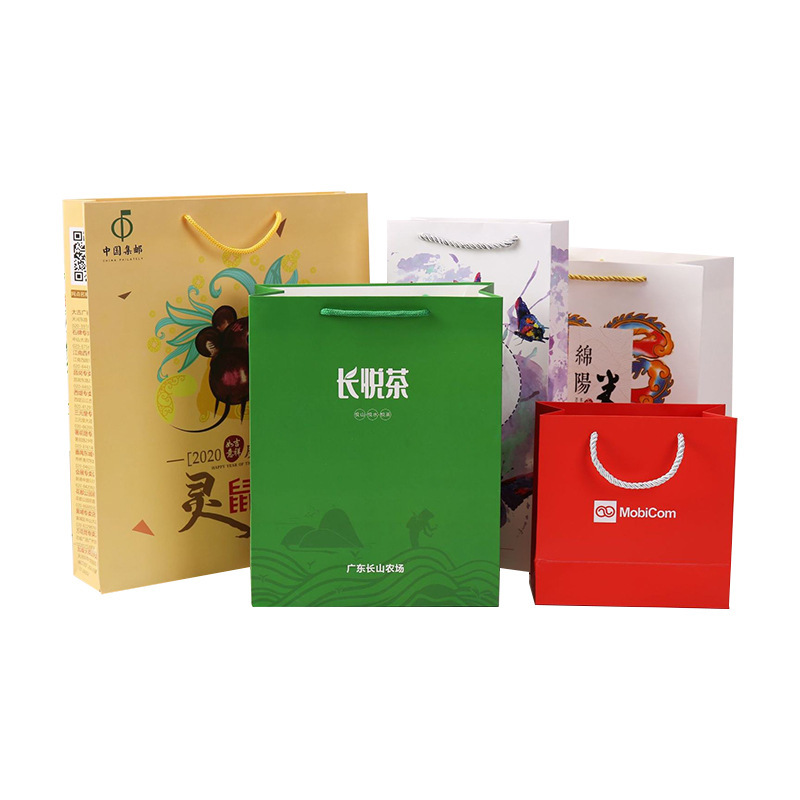

Handbag

Classification:

Shape: Rectangle

Dimension: 80*200*200mm 70*300*300mm 80*100*100mm Custom

Material: Coated paper/white cardboard

Printing: Monochrome/multicolor

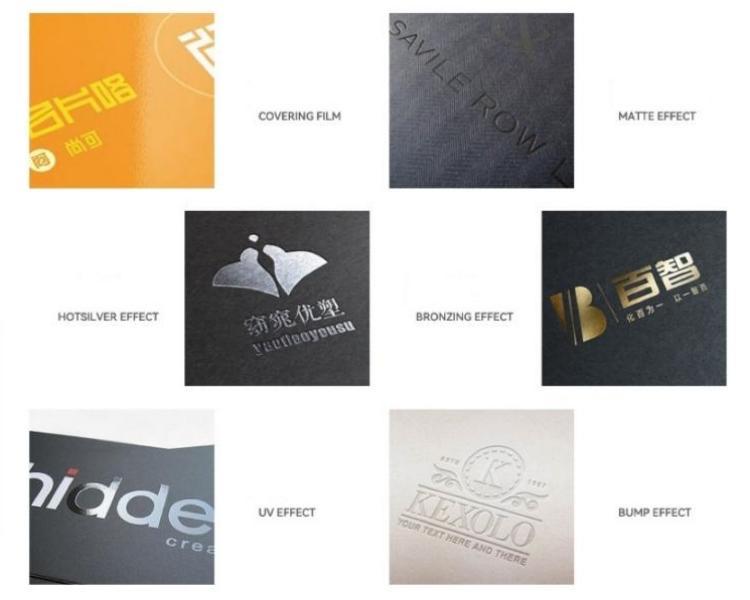

Options: Hot stamping, bump, local UV, window

£ 0.5-2.1/Price

500/PriceMinimum order quantity of Piece

Contact:

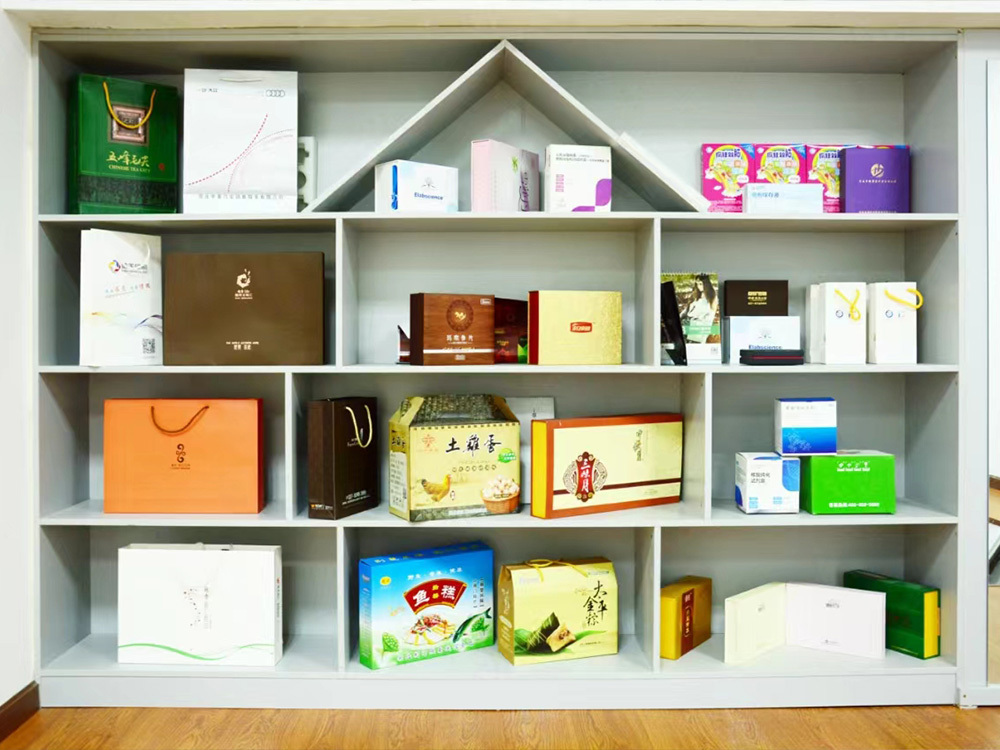

Related products

Details Introduction

1. White cardboard tote bag

The strength of white cardboard tote bags is the highest among all tote bags, which is determined by the physical properties of white cardboard. Designers generally use this type of tote bag to hold high-end clothing or goods. The white cardboard tote bag has a delicate touch, making it particularly elegant. White cardboard has good printability, and designers can boldly apply various design techniques (including color conception). White cardboard tote bag is the most expensive type of tote bag.

2. Copperplate paper tote bag

Choosing copperplate paper to make a handbag is characterized by moderate fastness. Due to its high whiteness and glossiness, copperplate paper has good printability, and designers can boldly use various images and color blocks, resulting in good advertising effects. After coating the surface of copperplate paper with a light film or matte film, it not only has moisture-proof and durable functions, but also appears more exquisite. Copperplate paper is the most popular material for making handbags.

Product Display

Craft Display

Packaging And Shipping

Customized product flow

1. Pre-sales consultation: Please confirm with our customer service staff the style, size, quantity, production process requirements and custom patterns of customized products, please contact us, we will give you an accurate quote.

2. Layout design: After confirming the quotation, if the layout is needed, we will contact the designer to design the sample.

3. Check the version type: After our designer designs the draft according to your requirements, we will give you a reference draft, if there is a need to improve, you can put forward your suggestions.

4. Confirm the final draft: After repeated communication and modification, the final draft is confirmed. Once it is confirmed, it cannot be changed.

5. Order production: After confirming the final draft, we will make it. If you need samples, we can provide them, and we will send them to you after they are completed.

6. Delivery: After completion, we will send the goods to you.

Looking forward to serving you, we believe that we will be the best choice for you.

Advantage Strength

Be Even Quality

The core team of DeMei has over 10 years of experience in the marketing and service industry, and has core professional competitive advantages in terms of service quality.

Fast Printing Speed

Always adhere to the business philosophy of "integrity management, excellence"; We have won a good reputation for Demei through unremitting efforts

Advanced Imported Equipment

Having advanced imported advertising and printing equipment; A comprehensive design and implementation solution.

One Stop Service

We will continue to provide our customers with warm, thoughtful, and perfect services, and create a win-win cooperation path together.

Equipment

FAQ

Q

What is a prepress fee? What does it include?

+

A

The pre-printing process is called the pre-press cost, and the processing procedure after printing is called the post-press processing cost. (Such as: typing, design, production, scanning, inkjet proofing/laser proofing, electrical/electrical proofing, receiving, proofreading, and bus fare are all pre-press charges. Post-printing processing is: hot stamping/silver, UV, convex and concave, embossing, laminating, indentation/folding, card point line/marking, card, sticking, cutting, packaging, freight, etc.

Q

Why is there a color difference between the printed color and the color displayed on the computer?

+

A

Display and color printing paper color formation is very different, the display is the use of blue, red, green three primary color principle to emit light to form an image, this color formation principle is called RGB, is widely used in television and computer monitors. Color printing is printed in four colors on paper products to form color images, this principle is called CMYK, is widely used in four-color offset printing technology. In addition, the cause of computer display and printed matter is that the color proofreading of the display itself is not adjusted well, so it is necessary to ask professional and technical personnel to adjust the display effect in time. Usually the difference in printing materials will also make the printing effect different, usually coated paper than offset paper printed out the effect of bright color. (Friendly reminder: digital proofing and printed sample color error and printed sample with computer display color error, there is a different difference, digital proofing slightly close to the printed product, but the computer display effect is often much brighter than the printed product, can not be said to be the same reference, so it is best to print proofing prevail.) Of course, chromatic aberration is unavoidable. Therefore, when making design drawings, CMYK design will be much closer to the truth than RGB design. Even if the design is made with RGB, it will be converted to CMYK color when printing.

Q

If there is no concept in the printing paper material, do not know what paper material to choose to print it, how to do?

+

A

General customers do not have a good understanding of the printed paper material, you can in the "paper material introduction" in the various paper material pictures, you can see the paper material applicable situation, you can compare and see which kind of paper material is suitable for your company! If you still have no idea, we can also help you make suggestions.

Q

The file has been prepared, but the file is very large, it is very slow to send to your company, and it is urgent to use the goods, how to solve it quickly?

+

A

Whether the image in your file has a large pixel, and has done a lot of effects, if so, we recommend that you use all effects, especially three-dimensional, shadow, image precision cropping to separate or transpose the map, so as to reduce the file size. (The bitmap pixel should be at least 350 CMYK format oh), of course, if your company is close to the company, you can also copy the file to yo!

Q

What resolution is needed for printing?

+

A

For printed documents, use vector files to print as much as possible (e.g. CDR, AI). If it is a PS file, the minimum must have 300 pixels, CMYK format, the general pixel set larger point, the effect is better! For printed documents, use vector files to print as much as possible (e.g. CDR, AI). If it is a PS file, the minimum must have 300 pixels, CMYK format, the general pixel set larger point, the effect is better!

Q

What are the commonly used materials of paper product packaging boxes?

+

A

Coated paper, kraft paper, white cardboard, grey board paper, gold, silver cardboard, special paper, industrial cardboard, corrugated paper,

Message consultation

Leave your phone number and we will contact you within 5 minutes;

Contact Information

Address: 2F, London Corporate Headquarters, UK